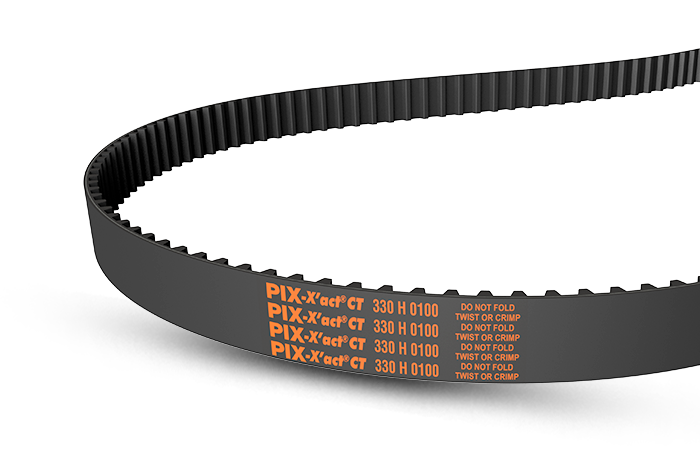

Everything You Need to Know About High-Strength Aramid Straps

High-strength aramid straps may not be something most people think about every day, yet they play a quiet but powerful role in many industries. From machines that work non-stop to systems exposed to heat, pressure, and constant movement, these straps are often the unseen heroes that keep everything running smoothly.

What makes them so special? Why are they trusted in situations where failure is not an option? And what should you really know before using them? Let’s explore the full story in a simple, clear, and practical way.

What Are High-Strength Aramid Straps?

High-strength aramid straps are made from aramid fibres, which are known for being extremely strong and resistant to damage. These fibres are lightweight but tough, and they can handle stress that would easily break many other materials.

In simple words, these straps are designed to:

- Carry heavy loads

- Survive high temperatures

- Last longer under pressure

- Stay stable in demanding environments

Unlike common materials that stretch, wear out quickly, or lose shape, aramid-based straps are built to keep their form and function for a long time.

Note: `

If you want to learn more about Aramid Straps(Correas de Aramida) and how they are used in real-world systems, PIX Spain offers helpful resources and insights. Contact them to explore practical knowledge and understand how these materials support modern industries.

Why Are Aramid Fibres So Strong?

The strength of aramid fibres comes from how their molecules are arranged. Instead of being loosely connected, they form tight and stable chains. This structure gives them a unique balance of flexibility and toughness.

This means aramid fibres can:

- Bend without breaking

- Resist tearing and cutting

- Maintain shape under stress

- Absorb shock and vibration

It’s this combination that makes them perfect for high-strength straps used in serious working conditions.

Key Features That Make These Straps Unique

High-strength aramid straps stand out because they offer several advantages at the same time. Most materials only excel in one or two areas, but aramid fibres bring multiple benefits together.

Here are the main features that define them:

- High load capacity without becoming bulky

- Strong resistance to heat and friction

- Low stretch even under continuous pressure

- Long life compared to standard straps

- Lightweight and easy to handle

This rare mix is why they are chosen for critical applications where safety and reliability matter.

Where Are High-Strength Aramid Straps Commonly Used?

These straps are used in places where normal materials simply cannot cope. You’ll often find them in industries that involve constant motion, heavy loads, or extreme conditions.

Some common areas include:

- Manufacturing machines

- Automotive systems

- Heavy equipment

- Lifting and handling tools

- Energy and power systems

In many of these cases, the straps are hidden inside machines, quietly doing their job without drawing attention. Yet, if they fail, the impact can be serious.

Performance Comparison Table

| Feature | Aramid Straps | Nylon Straps | Rubber Straps |

|---|---|---|---|

| Load strength | Very high | Medium | Low to medium |

| Heat resistance | Excellent | Poor | Medium |

| Stretch level | Very low | High | Medium |

| Lifespan | Long | Short to medium | Medium |

| Weight | Light | Light | Heavy |

This simple comparison shows why aramid-based straps are often chosen for demanding roles.

How Do They Handle Heat and Stress?

One of the most impressive qualities of aramid straps is how they behave under heat. Many materials weaken, soften, or even melt when exposed to high temperatures. Aramid fibres, however, remain stable.

They can continue working in environments where:

- Surfaces become hot

- Friction is constant

- Air temperature is high

- Movement is rapid and repeated

This makes them ideal for systems where heat is unavoidable and failure is not acceptable.

Durability and Long-Term Reliability

Durability is not just about how strong something is on day one. It’s about how it performs after months or years of use.

High-strength aramid straps are known for:

- Slow wear rate

- Resistance to cuts and surface damage

- Minimal shape change over time

- Consistent performance under pressure

This reliability reduces the need for frequent replacements, saving both time and effort in the long run.

Maintenance: Do They Need Special Care?

One of the reasons these straps are popular is their low maintenance nature. While they are not completely maintenance-free, they require far less attention than many alternatives.

Simple care tips include:

- Keeping them clean from dust and oil

- Checking for visible damage regularly

- Avoiding sharp edges in contact areas

- Storing in dry conditions when not in use

With basic care, they can easily outperform traditional materials in lifespan.

Common Myths About Aramid Straps

Despite their growing popularity, there are still a few misunderstandings about them.

Myth 1: They Are Too Rigid

In reality, aramid straps are flexible enough for most systems while still being strong.

Myth 2: They Are Only for Heavy Industry

They are used in both heavy and light applications where reliability matters.

Myth 3: They Don’t Wear Out

They do wear out eventually, but much slower than common materials.

Understanding these facts helps set realistic expectations.

Material Properties Table

| Property | Description |

|---|---|

| Tensile strength | Ability to handle strong pulling force |

| Heat stability | Maintains structure at high temperature |

| Chemical resistance | Not easily damaged by oils and solvents |

| Abrasion resistance | Withstands surface friction |

| Lightweight nature | Easy to install and handle |

These properties explain why aramid fibres are trusted in demanding environments.

How They Improve Safety

Safety is often overlooked until something goes wrong. High-strength aramid straps quietly reduce risks by being reliable and stable.

They improve safety by:

- Preventing sudden failures

- Reducing unexpected breakdowns

- Maintaining load balance

- Minimising vibration-related damage

In critical systems, this can mean the difference between smooth operation and costly accidents.

Environmental Impact and Sustainability

While no industrial material is perfectly eco-friendly, aramid straps have some positive points:

- Longer lifespan means less waste

- Reduced need for frequent replacements

- Lower resource use over time

Their durability indirectly supports sustainability by cutting down on constant manufacturing and disposal cycles.

The Future of High-Strength Strapping

The use of aramid fibres is expected to grow even more. As machines become faster and systems become more complex, the demand for strong and reliable materials will continue.

Future trends may include:

- Smarter designs using lighter materials

- Integration with advanced machinery

- Broader use in everyday industrial tools

What’s exciting is that many users still don’t realise how much these straps already support modern life behind the scenes.

Final Thoughts

High-strength aramid straps may seem like a small component, but they carry huge responsibility. Their strength, heat resistance, and long lifespan make them essential in systems that demand reliability.

Once you understand how much pressure, heat, and stress they can handle, it becomes clear why they are trusted in environments where mistakes are simply not allowed.

Sometimes, the strongest solutions are the ones you never notice—until you look closer.

FAQs

1. Are high-strength aramid straps better than steel straps?

In many cases, yes. They are lighter, easier to handle, and resistant to heat and corrosion, while still offering strong load capacity.

2. Can aramid straps stretch over time?

They have very low stretch compared to other materials. Any stretching that does occur is minimal and usually doesn’t affect performance.

3. Are they safe for continuous use?

Yes. They are designed for long-term operation in demanding conditions.

4. Do they work in wet environments?

They perform well in moisture and are not easily affected by water or humidity.

5. How often should they be replaced?

There is no fixed rule. Replacement depends on usage, environment, and visible wear, but they generally last much longer than standard straps.

Follow on Social Media

Facebook: https://www.facebook.com/pixgermanygmbh/

Instagram: https://www.instagram.com/pixgermanygmbh/

YouTube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixgermanygmbh/

Twitter: https://x.com/pixgermanygmbh

Google Maps: https://maps.app.goo.gl/Ls83bzangT1ipdQv5

For more infotactic content visit enterprisingcore